Before going to know the uses of cooled capacitors, it is important to understand “What are Water-Cooled Capacitors?”. It is a cut-edge, innovative electrical instrument to store and transfer electrical energy. These capacitors, unlike traditional air-cooled capacitors, employ a water-based cooling system to efficiently dissipate heat generated during operation. By utilizing water as a cooling medium, these capacitors can handle higher power loads and deliver optimal performance, making them an ideal solution for demanding applications.

Where to Use & Applications of Water Cooled Capacitors?

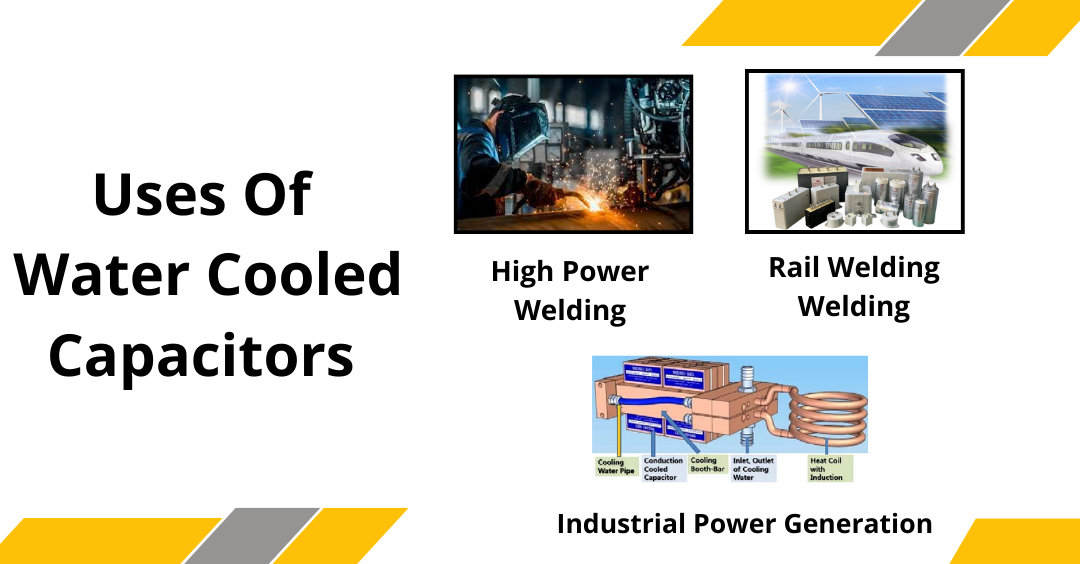

Water-cooled capacitors find wide applications in various industries for RF applications including induction heating, welding, and dielectric heating systems. Some common areas where these capacitors are utilized include:

â–º Industrial Power Electronics: Water Cooled Capacitors play a crucial role in smoothing out power fluctuations, filtering harmonics, and enhancing the efficiency of industrial power electronics like variable frequency drives (VFDs) and induction heating equipment.

â–º Renewable Energy Systems: In wind and solar power generation systems, Water Cooled Capacitors are used to stabilize the output, compensate reactive power, and ensure grid compatibility.

â–º Welding Equipment: The high-energy demands of modern welding machines require efficient capacitors for energy storage and discharge. Water Cooled Capacitors excel in this regard, providing reliable and consistent performance.

â–º Pulse Power Applications: Water Cooled Capacitors are employed in pulsed power applications like pulsed lasers, electromagnetic forming, and particle accelerators, where rapid energy discharge is required.

â–º Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs): The automotive industry is also exploring the potential of Water Cooled Capacitors to enhance the efficiency and power handling capabilities of EV and HEV powertrains.

Raw Materials Used in Manufacturing Water Cooled Capacitors

The construction of Water Cooled Capacitors involves high-quality materials to ensure their safety and durability. Some essential components used in their manufacturing include:

â–º Metallized Film: Typically made from materials like polypropylene or polyester, metalized films are used as the dielectric medium in these capacitors.

â–º Electrodes: High-purity metal foils such as aluminum or copper are used as electrodes to facilitate energy storage and transfer.

â–º Water-Carrying Tubes: High-grade tubing, often made from stainless steel or other corrosion-resistant materials, is used to circulate water around the capacitor's core, dissipating heat effectively.

â–º Cooling System: A well-engineered cooling system, including pumps, heat exchangers, and temperature sensors, ensures efficient cooling of the capacitor.

Which Sectors Can Benefit from Water-Cooled Capacitors?

The versatility and performance of Water Cooled Capacitors make them indispensable in several sectors:

â–º Manufacturing: Industries relying on heavy machinery and automated processes can benefit from increased power stability and efficiency provided by Water Cooled Capacitors.

â–º Energy & Power Generation: Power plants, especially those utilizing renewable energy sources, can utilize these capacitors to enhance their output and grid stability.

â–º Electronics & Semiconductors: Water Cooled Capacitors play a vital role in maintaining the integrity of sensitive electronics and ensuring smooth operation.

â–º Transportation: Electric and hybrid vehicles can make use of these capacitors to improve energy management and extend battery life.

Benefits of MV Capacitor & Water Cooled Capacitors

Moreover, Water Cooled Capacitors represent a significant leap forward in capacitor technology, providing unmatched performance, efficiency, and reliability across various industrial applications. As industries continue to push the boundaries of power and automation, these capacitors are poised to play a crucial role in shaping the future of electrical systems.